flange discs and Plastic pipe end caps ,flange cover and Heavy duty surface protection

flange discs and Plastic pipe end caps ,flange cover and Heavy duty surface protection

Half round pads: https://book.yunzhan365.com/jrlbf/ozrv/mobile/index.html

Why big size plastic pipe end caps is safety and cheap then big size inject molds plastic pipe end caps?

Not easily deformable, highly customizable, shape and size customizable, no molds required plastic pipe end caps Not easily deformable, highly customizable, shape and size customizable, no molds required

https://youtube.com/shorts/gf4BHcqPsrA

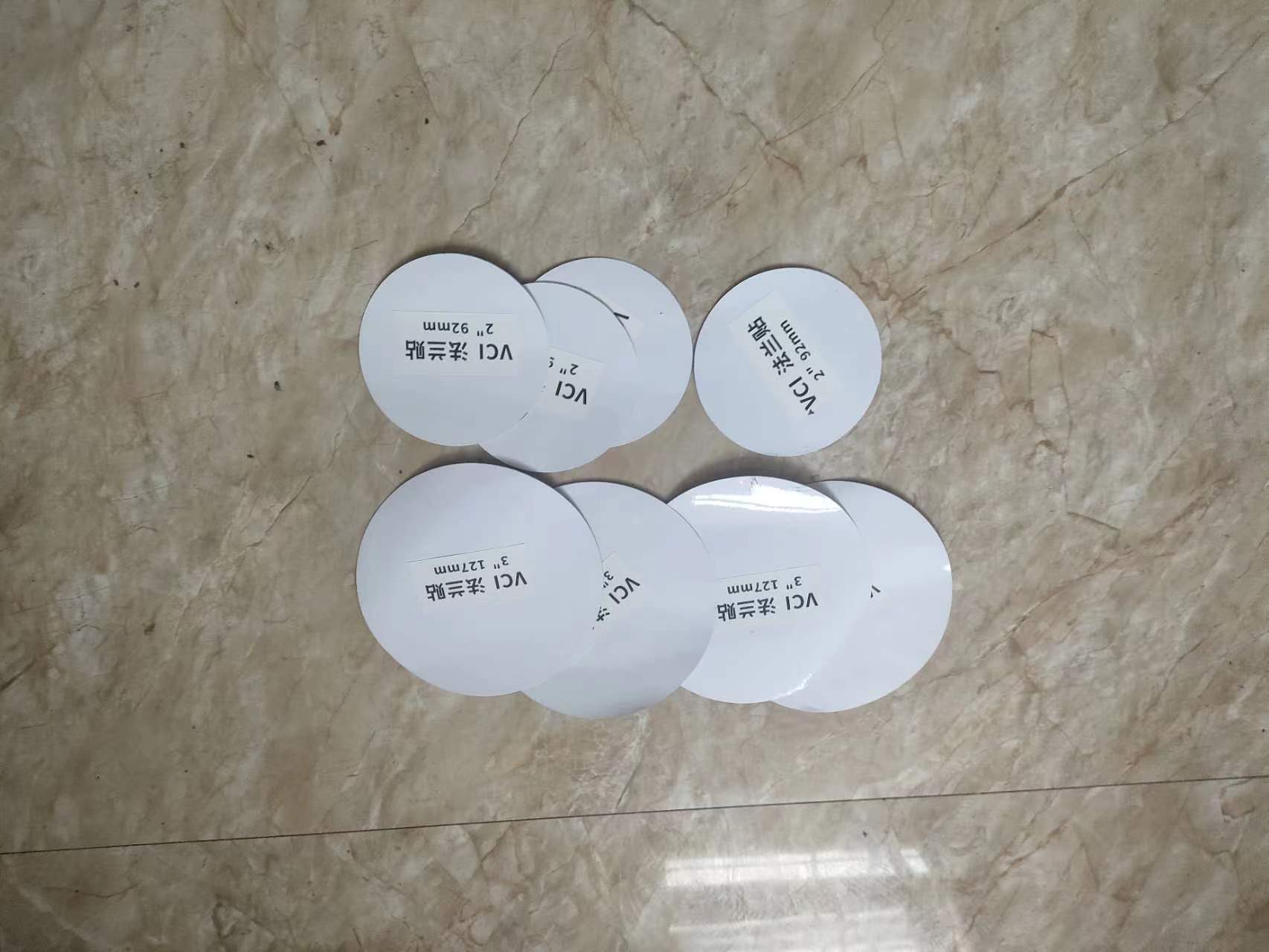

1.VCI dip coating technology

VCI Dip coating is a simple and versatile manufacturing process for applying a uniform layer of liquid(add VCI) or powder(Add VCI) to an object by submerging it in a tank and then withdrawing it.

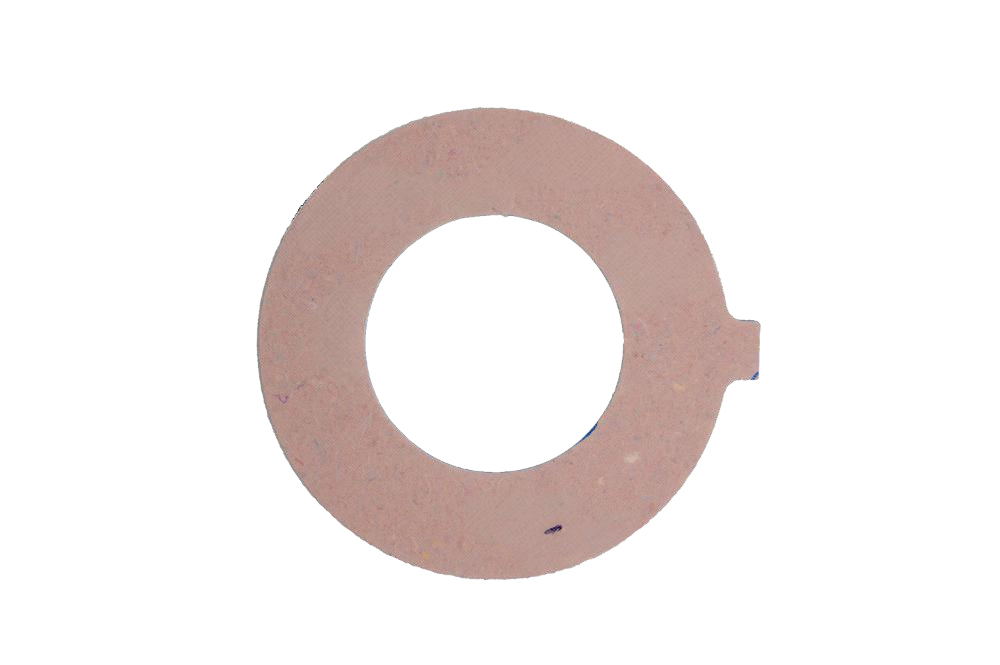

Why need 2mm self adhesive Waterproof pressboard flange or pipe end cover

2mm self-adhesive waterproof pressboard flange or pipe end covers arises from several key reasons related to protection, durability, and customization in industrial applications. These covers serve to protect the flange or pipe ends during storage, transport, or periods of inactivity

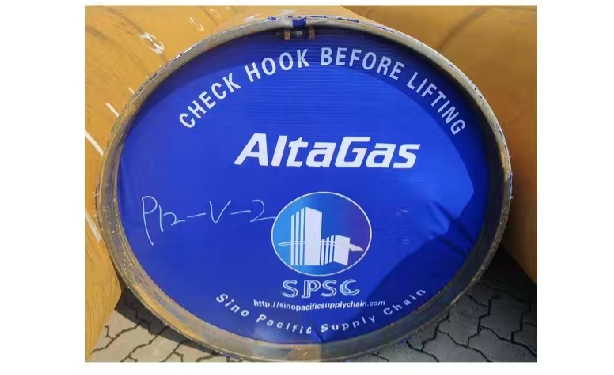

Using a metal pipe end cap bevel protector with canvas to replace big size plastic plugs for moving pipes during storage, transit, and laying has several advantages, especially when crane hooks are involved in moving large pipes. Here’s why the metal pipe end cap bevel protector is a better option:

https://www.youtube.com/watch?v=J9kH1DQEYdg

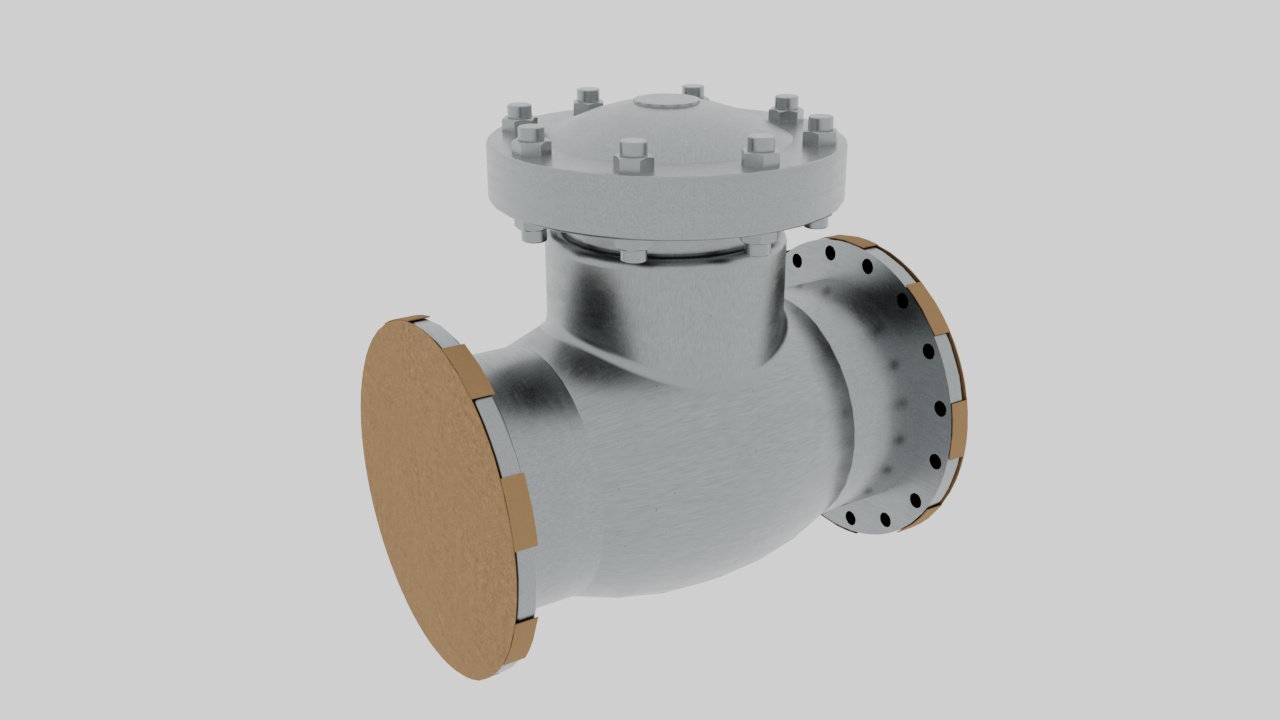

1.Flange

VCI raised-face flange protectors are self-adhesive covers designed to protect sealing surface

1. VCI self adhesive flange discs

The adhesive flange protectors are capable of withstanding the most aggressive blast medias. Additionally, they prevent the ingress of unwanted contamination into all your piping components. they can be installed and removed rapidly. Furthermore, no adhesive residue is left behind, eliminating the need for subsequent cleaning.

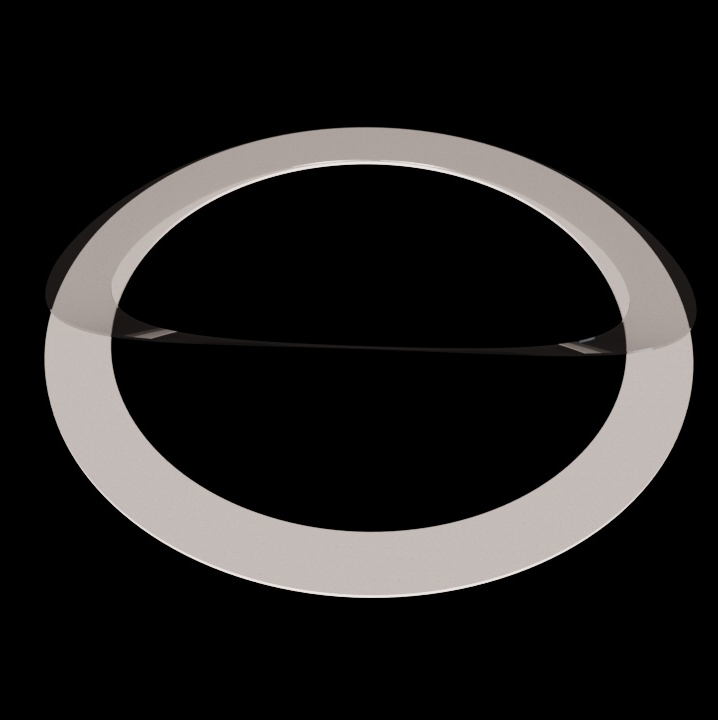

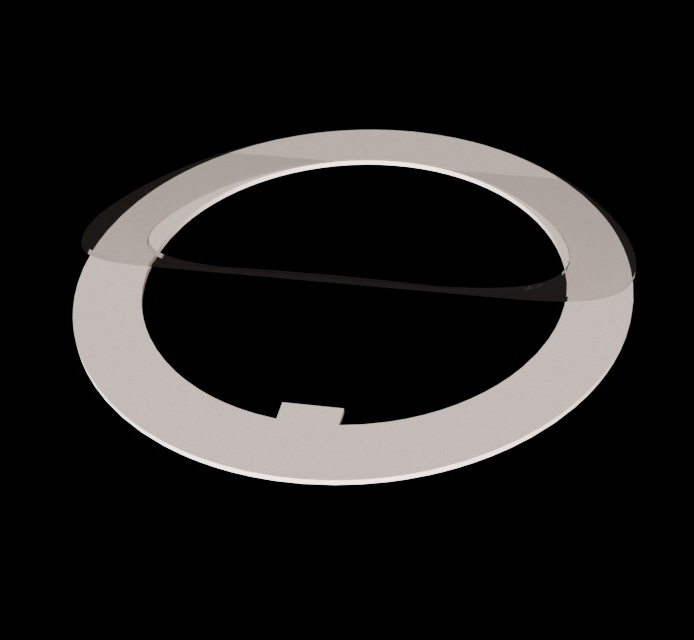

2. VCI self adhesive flange ring type discs

Most using in paint and welding protection ,The components are precision-cut to align with the contours of the raised surface, ensuring a precise and clean paint edge.

3, VCI Flange with tags

The tag serves to indicate the status of the installation.

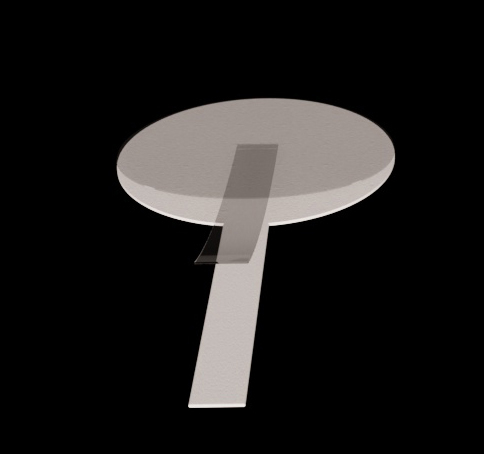

4. VCI Self adhesive Pipe sleeve or Pipe Closure

Pipe inside with Vci Powder Packet

We believe that Flange Strong Magnetic +VCI is very suitable for short, medium and long term storage of carbon steel and is the most effective adhesive flange protector currently on the market

Forms an airtight, waterproof seal on the flange surface even on oily surfaces

This product can be used during welding and fabrication processes, as well as in preparation for sandblasting and painting, to prevent contamination of your steel components. It can also provide ideal flange surface protection for hydrostatic testing of carbon steel valves, and the flange can be painted and sandblasted

Can be reused

Most corrosion inhibitors allow flanges to magnetically discs without removal

During pipeline prefabrication or valve production, any working conditions can be written on the flange magnetic discs.

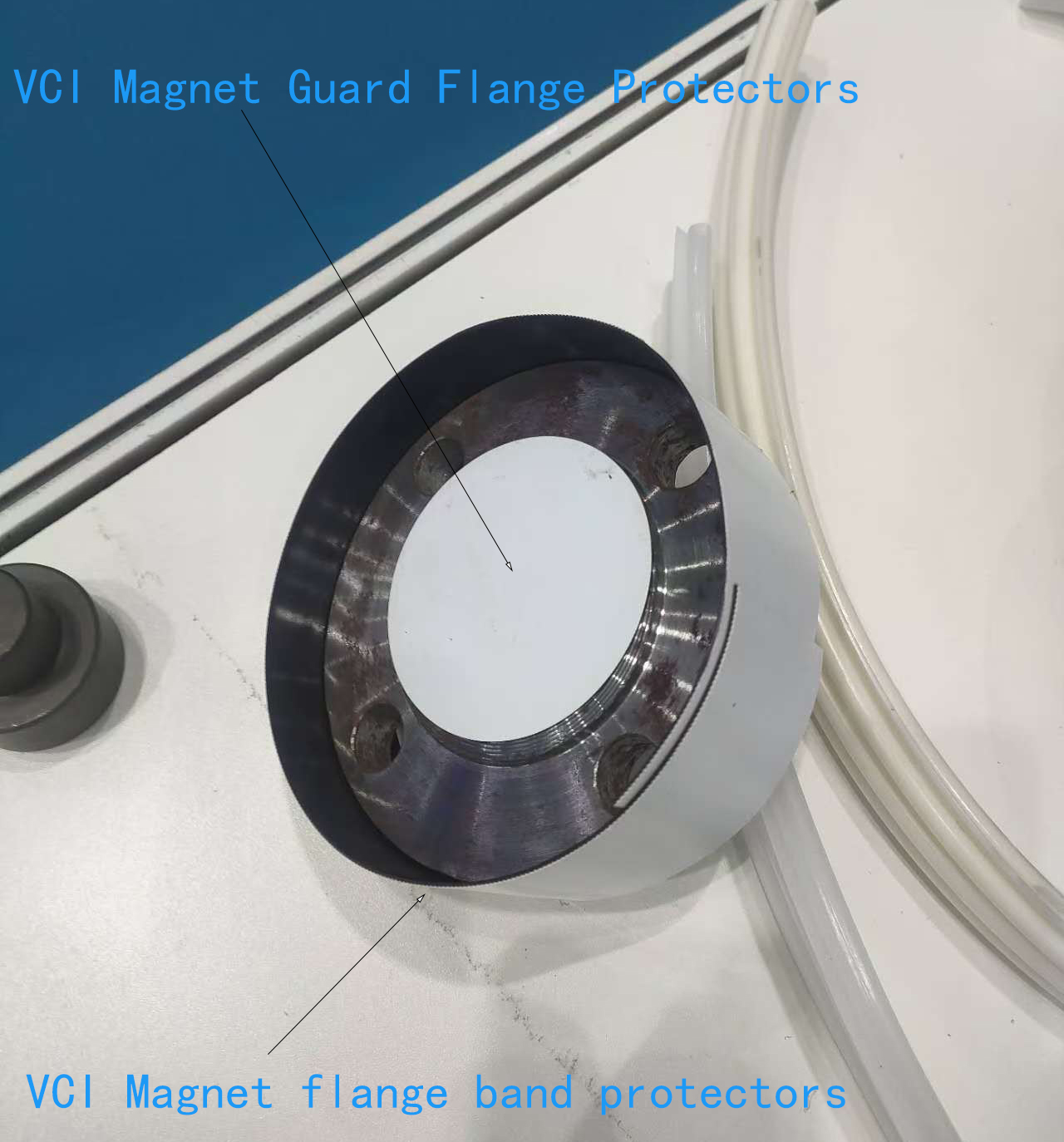

What is VCI flange band protectors

Corrosion Protection: The VCI oil releases corrosion-inhibiting vapors that form a protective layer on metal surfaces, preventing moisture and corrosive substances from causing damage.

Easy Application: The magnetic design allows for easy attachment to flanges without the need for additional fasteners or adhesives, making installation quick and efficient.

Reusable: Many VCI magnet flange protectors can be reused, which makes them a cost-effective solution for ongoing protection.

Compatibility: They can be used with various flange types and materials, making them versatile for different industrial applications.

Maintenance Reduction: By providing effective corrosion protection, these protectors help reduce maintenance needs and extend the life of flanged connections.

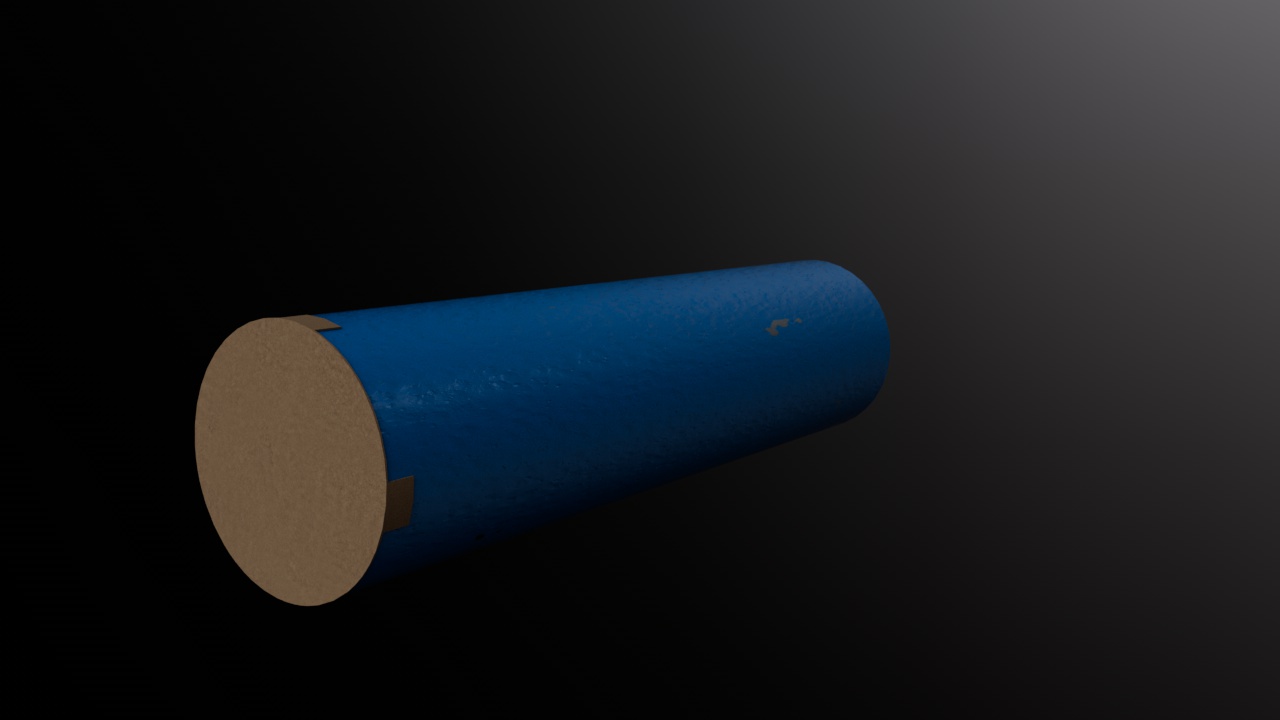

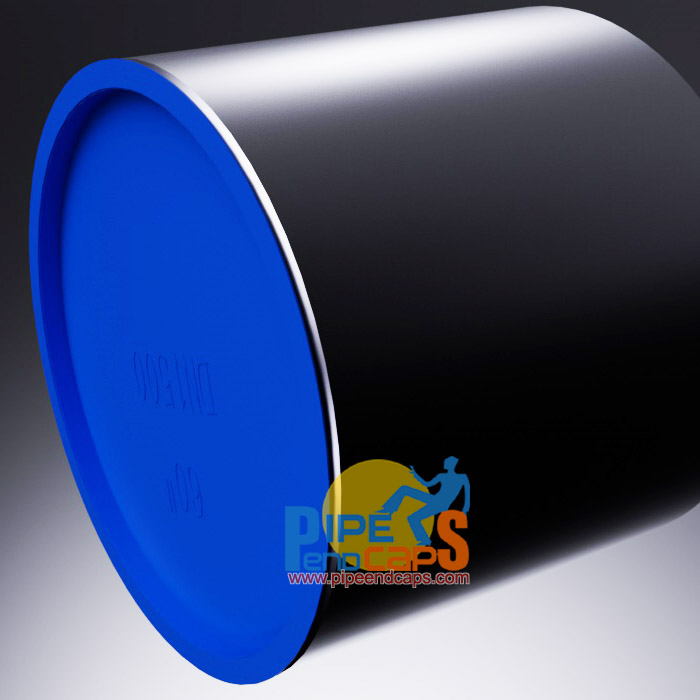

1.Plastic pipe end caps and plugs are protective covers that are designed to be installed on the ends of plastic pipes to protect them from damage and debris during transport, storage, and installation. They can also help to prevent the contamination of the pipe and maintain its integrity during shipping and storage.

Plastic pipe end caps and plugsare made of various types of materials, including polyethylene, polypropylene, and PVC. They can come in different sizes and shapes to accommodate different types of pipes and fittings, including round, oval, and rectangular.

Plastic pipe end caps and plugs serve a variety of purposes. They can prevent dust, dirt, and debris from accumulating inside the pipe, protect against damage caused by moisture, and keep the pipe clean during storage and transport. They can also help to prevent the pipe from being damaged during handling, and they can act as indicators to help identify different types of pipes.

Overall, Plastic pipe end caps and plugs are an essential component of protecting and maintaining the integrity of plastic pipes, preventing contamination and damage that can occur during shipping, handling, and storage. They are a cost-effective and easy-to-use solution that can be applied to a wide range of pipes and fittings, and help to ensure that plastic pipes remain in good condition and function properly.

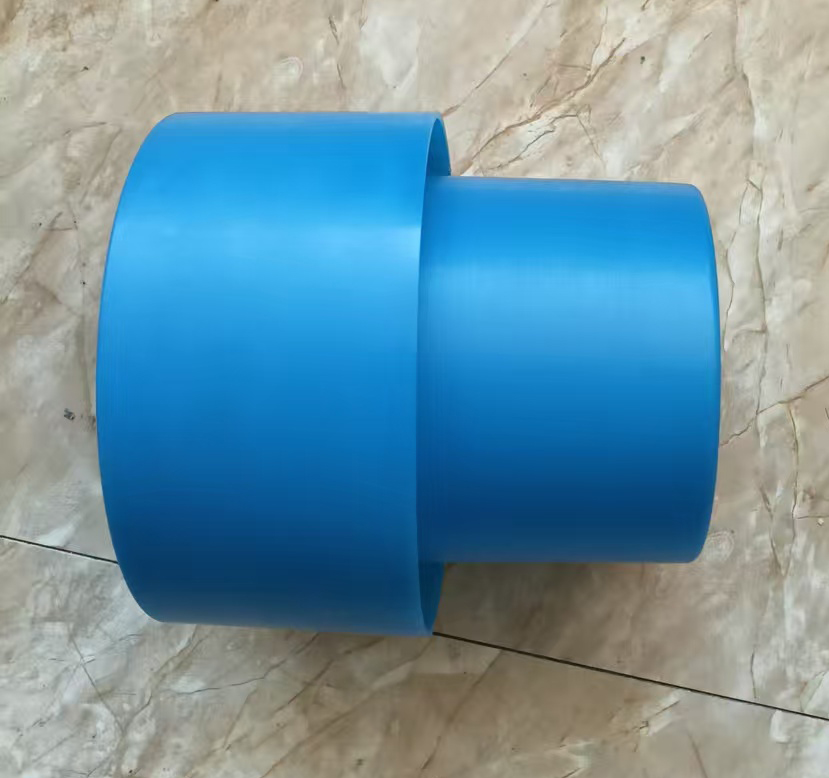

2.Pipe PTC caps

pipe PTC covering or cap is used during the painting process to prevent any quality issues from grit or dust inflow. These particles can damage the paint job and affect the integrity and longevity of the pipe. The covering ensures a smooth and clean painting process, preventing uneven paint application, rough texture, or premature chipping or peeling. Therefore, it's a crucial step in maintaining the quality of painted pipes.

https://www.youtube.com/watch?v=FBlsPEeVHwI

https://www.youtube.com/watch?v=QvHI2kK51cA

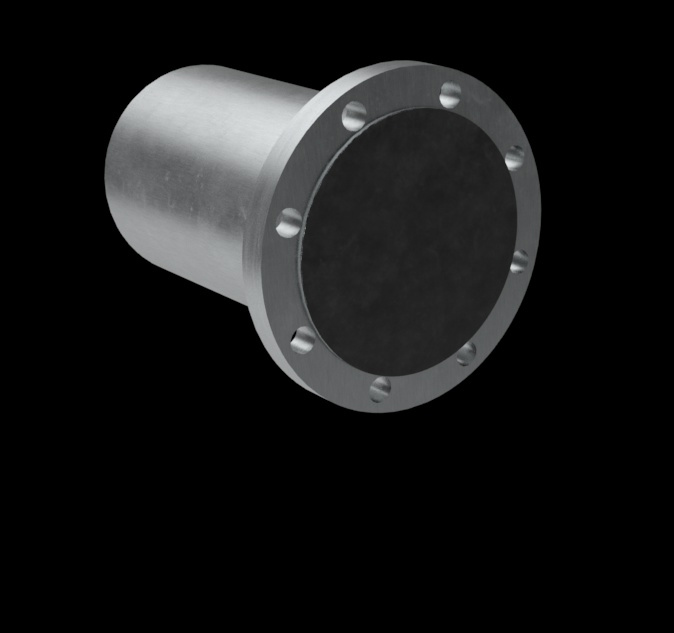

3.Pipe bevel protection

The Bevel Protector is essential for safeguarding the integrity of the pipe-end, particularly during transport and handling, where impact damage can easily occur.

Its design offers robust protection for all kinds of steel and various bevel designs, ensuring that the shape and structure of the pipe end are maintained. This is crucial, as deformations can potentially impair the pipe's effective connection, leading to leakage or other functional issues later.

In addition to the Bevel Protector, a plug also serves an essential role in protecting pipes. It keeps the inner space of the pipe safe from contamination by dirt, moisture, and other foreign materials, which can affect the quality of fluids being transported in the pipe or even cause corrosion

or other damage to the inner pipe wall.

The combined use of a Bevel Protector and a plug, therefore, can greatly enhance the longevity and performance of pipe systems. They can help to prevent functional issues, reduce maintenance needs, and ensure that the pipes deliver a reliable and efficient performance over time.

4.VCI pipe caps add VPCI bag protects

VCI (Volatile Corrosion Inhibitor) pipe caps and VPCI (Vapor Phase Corrosion Inhibitor) bags are extremely beneficial in preventing corrosion and maintaining the integrity of the pipes, especially in storage and transport.

VCI pipe caps are infused with corrosion inhibiting compounds that release vapors and form a protective layer on the surface of the pipe. This protective layer effectively prevents rust and other forms of corrosion that could weaken the pipe over time, thus ensuring the longevity and performance of the pipe.

VPCI bags work in a very similar manner. They release corrosion inhibiting vapors that form a thin, protective layer on all the metal surfaces within the bag, providing excellent protection particularly during long term storage or shipping.

Together, they ensure that the pipes stay clean and intact, ready for use. Both are a cost-effective way to safeguard your investment in pipes, particularly for high-value materials like stainless steel or other alloy pipes.

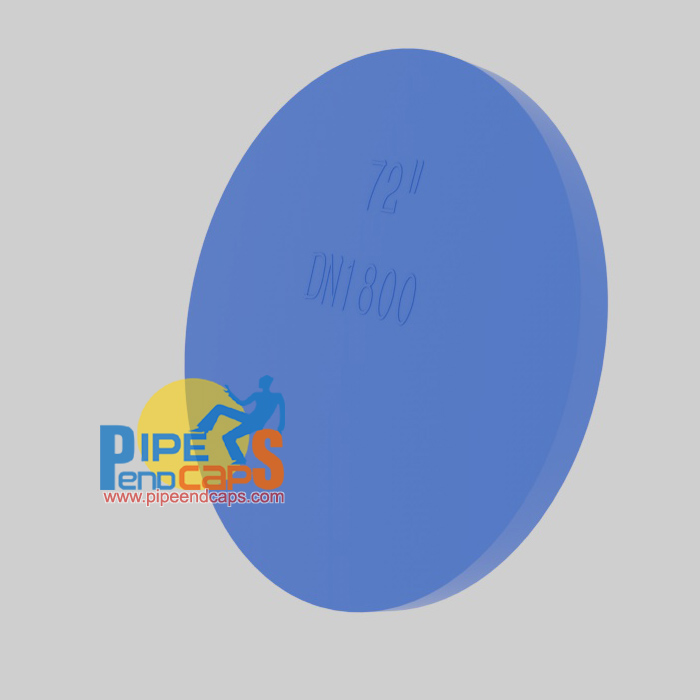

1. Plastic pipe end caps

Plastic pipe cap end protectors protect the bevel ends of pipe from damage in storage space}and shipping.

Plastic end caps keep carefully within the pipe clean from dirt, debris and critters.

These protective caps last years away in the surroundings because their sturdiness and natural UV resistance.

2.Plastic pipe Plugs

Plastic pipe plugs are designed to t storage, or transportation of piping systems, as well as to protect pipes from dirt, debris, and contaminants. These plugs are typically

made from materials like LDPE (Low-Density Polyethylene), or other types of plastic,

depending on the application and compatibility with the pipe material.

There are several types of plastic pipe plugs, including:

Threaded plugs: These plugs have external threads that are designed to screw into the internal threads of a pipe or pipe fitting. This creates a secure and tight seal, making them suitable for use in pressurized systems.

Push-fit plugs: Push-fit plugs are designed to be inserted into the end of a pipe or pipe fitting, creating a friction fit. They are easy to install and remove, making them ideal for temporary sealing or testing purposes.

Expansion plugs: Expansion plugs use a mechanical mechanism, such as a threaded bolt or cam, to expand the plug against the inner walls of the pipe or pipe fitting, creating a tight seal. These plugs are commonly used for pressure testing or to seal pipes with varying internal diameters.

Tapered plugs: Tapered plugs have a conical shape that allows them to be inserted into the end of a pipe or pipe fitting, creating a snug fit. They are often used for temporary sealing or testing purposes.

Flanged plugs: Flanged plugs have an integrated flange that fits against the end of a pipe or pipe fitting, providing an additional sealing surface. They can be secured with bolts or straps and are commonly used for temporary or permanent sealing in high-pressure applications.

When selecting a plastic pipe plug, it is important to c

this type is designed inserted ribbed ,perfit inside pipe clean from dirt.

3.Fabric Pipe and Flange Covers

Fabric pipe caps are covers designed to protect the open ends of pipes from dirt, debris, and environmental contaminants during storage, transportation, or maintenance. They are made from flexible and durable materials, such as polypropylene, polyester, or other specialized fabrics, which can resist chemicals, moisture, and UV exposure.

Fabric pipe caps can be used for various pipe materials, including metal, PVC, or HDPE pipes. They are typically secured using elastic bands, drawstrings, or adjustable straps, making them easy to install and remove as needed.

Some advantages of using fabric pipe caps include:

Customizability: Fabric pipe caps can be custom-made to fit specific pipe dimensions and shapes, providing a secure and snug fit.

Easy installation and removal: The flexible nature of fabric caps makes them easy to install and remove without the need for specialized tools.

Reusable and durable: High-quality fabric pipe caps are reusable and can withstand harsh environmental conditions, making them a cost-effective solution for pipe protection.

Versatility: Fabric pipe caps can be used with various pipe materials and in different industrial or construction settings.

When selecting fabric pipe caps, it is essential to consider factors such as the pipe material and dimensions, the environment in which the pipe will be stored or used, and any specific chemical resistance requirements. Properly installed fabric pipe caps can help protect pipes from damage and maintain the overall integrity of the piping system.onsider factors such as the pipe material, operating pressure, temperature, and the type of fluid being transported. Properly installed pipe plugs can help protect pipes, maintain system integrity, and prevent accidents or leaks.

most protector no standward pipe or big size caps ,and coating protection

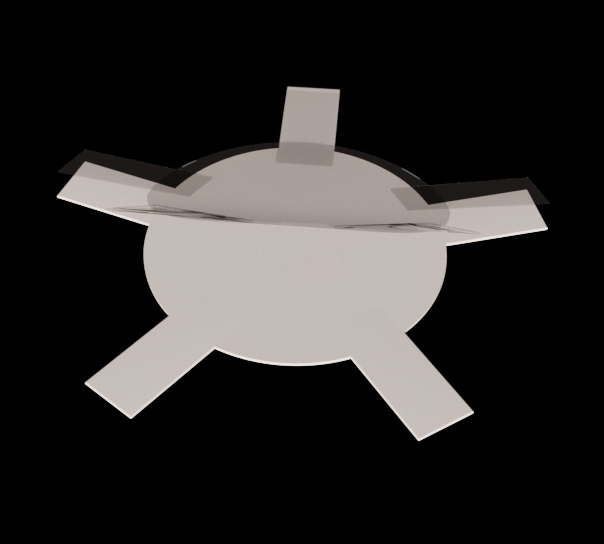

4.Bevel Protector with soft plugs

Pipe bevel protectors with soft plugs are designed to protect the beveled ends of pipes during storage, transportation, or maintenance. These protectors are particularly useful for pipes that will be welded or joined, as they help maintain the integrity of the bevel and prevent damage to the pipe ends.

A pipe bevel protector with a soft plug typically consists of two parts:

Bevel protector: This is a rigid outer shell made from materials like plastic or metal that fits over the beveled end of the pipe, providing a protective barrier against impacts, dirt, and debris. The bevel protector may have a flange or lip that sits against the end of the pipe to ensure proper positioning and a secure fit.

Soft plug: The soft plug is made from a flexible and compressible material, such as foam, rubber, or silicone. This plug is inserted into the open end of the pipe, creating a friction fit that seals the pipe and helps prevent the ingress of dirt, moisture, and contaminants. The soft plug material should be chosen based on compatibility with the pipe material and any specific environmental or chemical resistance requirements.

When selecting a pipe bevel protector with a soft plug, it is important to consider factors such as the pipe material, dimensions, bevel angle, and the environment in which the pipe will be stored or used. Properly installed bevel protectors and soft plugs can help protect pipes from damage and maintain the overall integrity of the piping system.

Bevel Protector with plugs

8" to 120"

This Plugs design prevents penetration from water,oil dirt and dust.it is closure with two end of pipe.

Plugs material: EPDM sheet/Nylon/ PVC with net

1.low cost

2.suitable for long term pipe storage

3.suit for hook lifting

Use flange spray shields in pipe connections

5.Vinyl PVC End Caps

Vinyl PVC end caps are protective covers designed to fit over the ends of PVC pipes, tubes, rods, or other similar structures. They serve various purposes, including:

Protection: End caps can protect the ends of PVC pipes and other structures from damage due to impact, abrasion, or exposure to harsh environments.

Sealing: When fitted tightly, end caps can help prevent the ingress of dirt, moisture, and other contaminants into the pipe or tube.

Aesthetics: By covering the exposed ends of PVC structures, end caps provide a clean, finished appearance.

Safety: End caps can cover sharp edges, reducing the risk of injury for those handling the PVC material.

Vinyl PVC end caps are available in various sizes, shapes, and colors to accommodate different applications and design preferences. When selecting end caps, be sure to choose the appropriate size and style for your specific PVC structure. Installation is generally simple, as the end caps can be pushed onto the ends of the pipes or tubes. In some cases, adhesive may be used to secure the end cap in place for a more permanent solution.

To find vinyl PVC end caps, consult your local hardware store or search online for suppliers who specialize in PVC products.

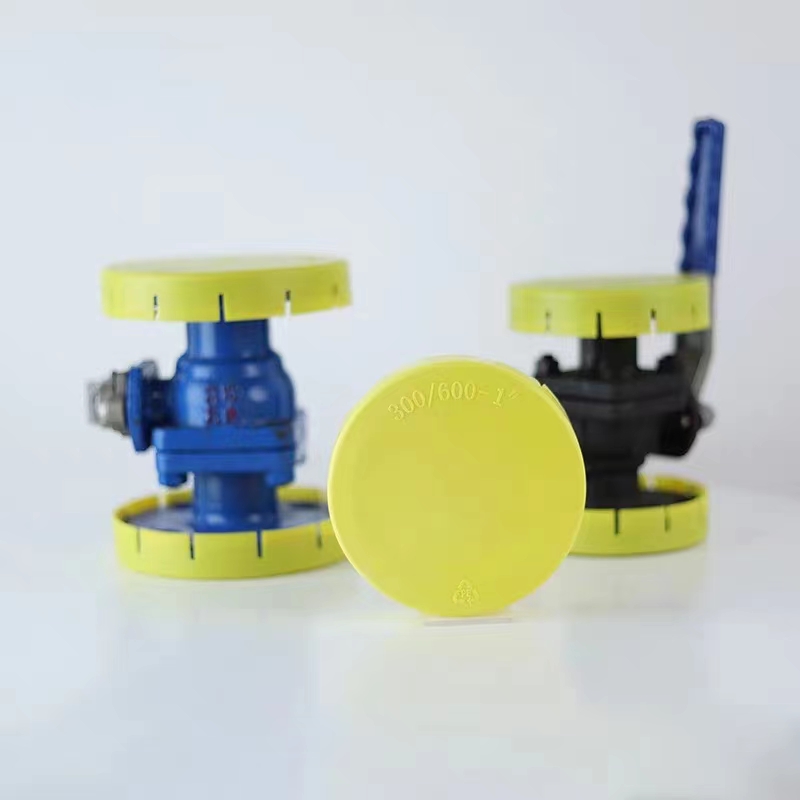

What is flange cover?

Flange covers are protective covers that are used to protect flanges from damage or contamination during transportation, storage, or installation. They are designed to fit over the flanges and can be made from a variety of materials including plastic, rubber, or metal. Flange covers are available in a range of sizes and types to fit different flange configurations and applications. Some common types include bolt-hole covers,

full face covers, and ring type covers. Flange covers help to ensure that the flanges remain clean, corrosion-free, and protected during shipping and handling until they are ready for use.

1.Raised Face Flange Protectors

Raised face flange protectors are designed to cover and protect the raised face surface of flanges during storage, transportation, or maintenance. The raised face is a critical sealing surface on flanges, and protecting it from damage, dirt, and debris is essential for maintaining the integrity of the piping system.

Raised face flange protectors are typically made from various materials, such as plastic, rubber, or metal, depending on the application and compatibility with the flange material. These protectors can be custom-made to fit specific flange dimensions, including the outer diameter, bolt circle diameter, and the number of bolt holes.

There are several types of raised face flange protectors, including:

Snap-on protectors: These protectors are designed to snap onto the raised face surface of the flange, providing a secure and tight fit. They are typically made from plastic or rubber materials and can be easily installed and removed without the need for tools.

Bolt hole flange protectors: Bolt hole flange protectors are designed to cover the entire flange face, including the bolt holes. They are usually made from plastic or metal and are secured to the flange using the existing bolt holes, providing a secure and stable protection.

Push-in protectors: Push-in protectors are designed to be inserted into the bolt holes of the flange, protecting the raised face surface. They are typically made from plastic or rubber materials and provide a friction fit, making them easy to install and remove.

Full face protectors: Full face protectors cover the entire flange face, including the raised face surface and the bolt holes. They can be made from various materials, such as plastic, rubber, or metal, and are secured with straps, fasteners, or integral locking mechanisms.

When selecting a raised face flange protector, it is important to consider factors such as the flange material, dimensions, and the specific environmental or chemical resistance requirements. Properly installed raised face flange protectors can help protect flanges from damage and maintain the overall integrity of the piping system

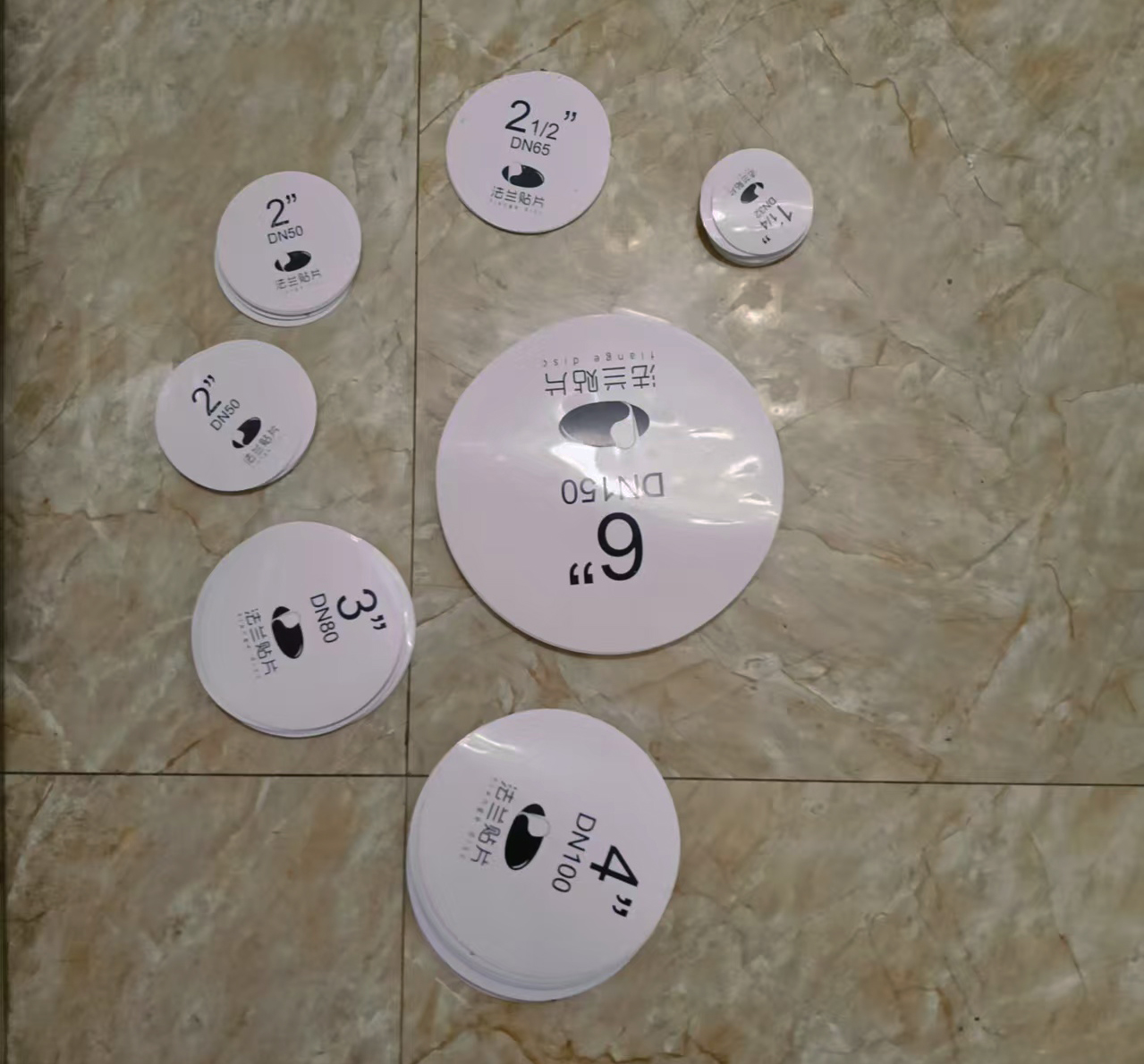

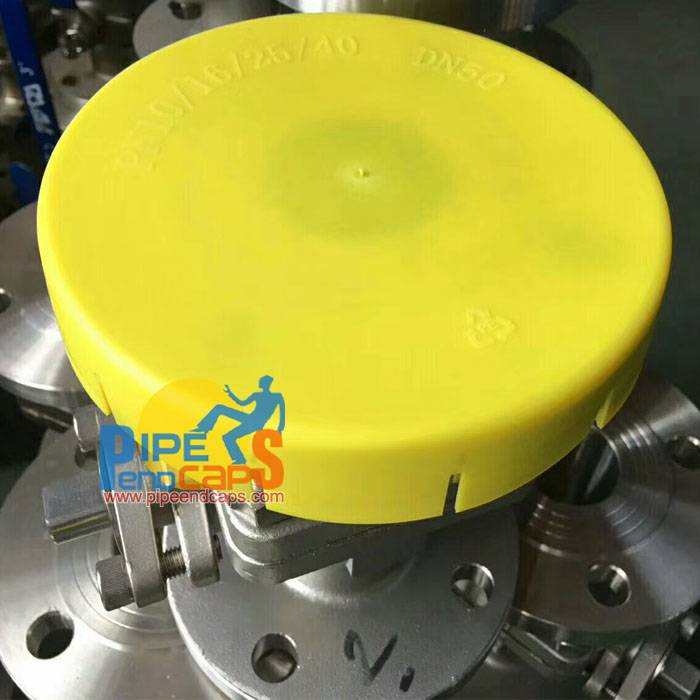

3.1 Plastic Flange caps

Plastic flange caps are used to protect flanges, which are typically found on pipes and used to connect, end or block a run. The caps are designed to safeguard the integrity of the flange against damage and contamination by covering

the full face of the flange.

They are usually constructed from durable plastic materials resistant to moisture, dirt, and other corrosive elements. Moreover, they are available in various sizes and configurations to accommodate different types and sizes of flanges.

With their simple push-fit application, they offer a quick and efficient method of flange protection without the need for additional fasteners. Additionally, their bright colors often help to enhance visibility and identification for safety purposes.

In essence, plastic flange caps offer an economical and reliable solution to shield flanges from potential hazards during storage, transportation, and even throughout the duration of the installation project until the need for the flange to be exposed and used

2.Outside Fitting Flange protections

An outside fitting flange cover provides full protection for flanges used in industrial settings. These coverings shield the flange from damage and exposure to contaminants, ensuring it remains in optimal shape and extends the lifespan of the flange.

An outside fitting flange cover wraps around the entire surface of the flange. It is typically manufactured from plastic or metal to withstand harsh industrial environments. These covers come in various sizes and configurations to fit a wide range of flanges.

Some of the features of full flange covers can include:

Designed to protect the exposed flanges from the possible scratches during handling, shipping, and storage.

Easy to install and remove without any additional tools or equipment.

Custom sizes and designs are available to fit varying types of flanges.

Robust construction to withstand environmental elements and resist impacts.

Capable of bearing high temperatures and heavy load.

Full flange covers are commonly used in industries like oil and gas, petrochemicals, chemical processing, water treatment, and other applications where flanges are extensively used for connecting pipes, pumps, and valves. Their major aim is to minimizes the need for costly replacements and repairs caused by damage.

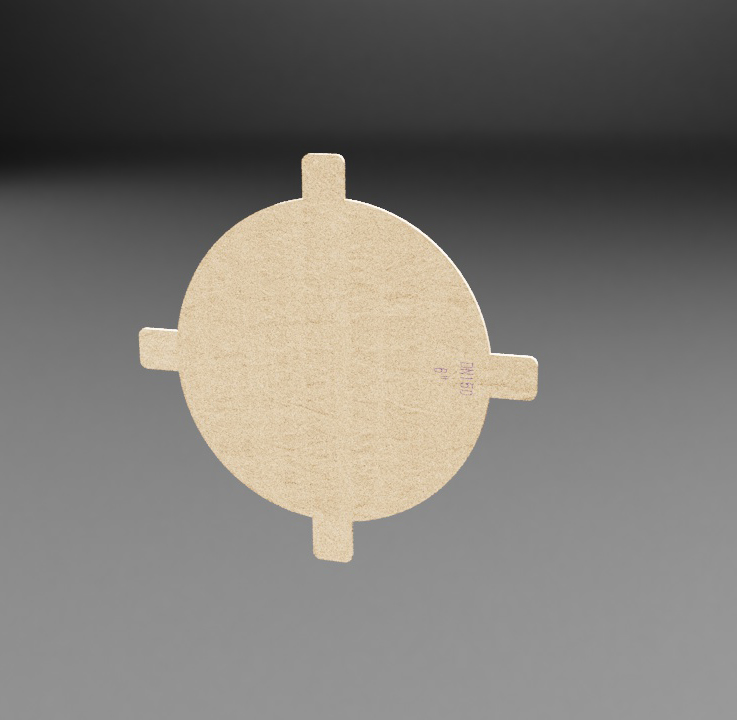

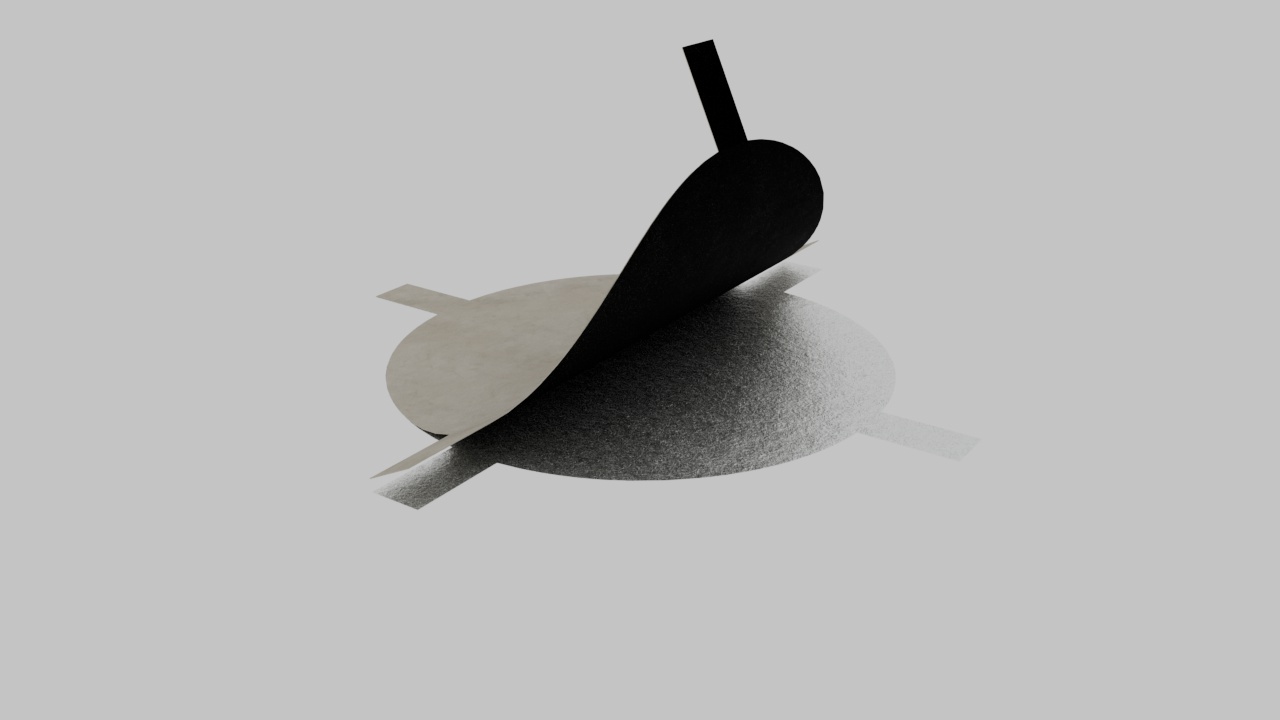

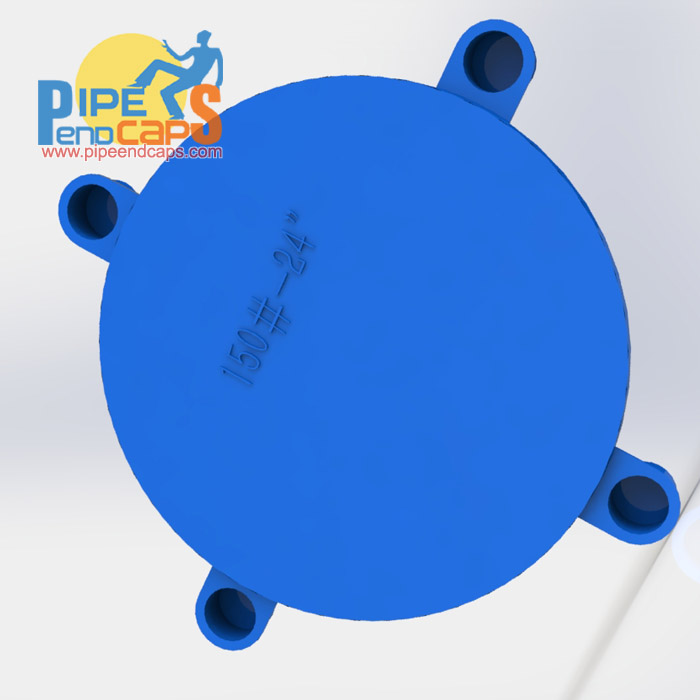

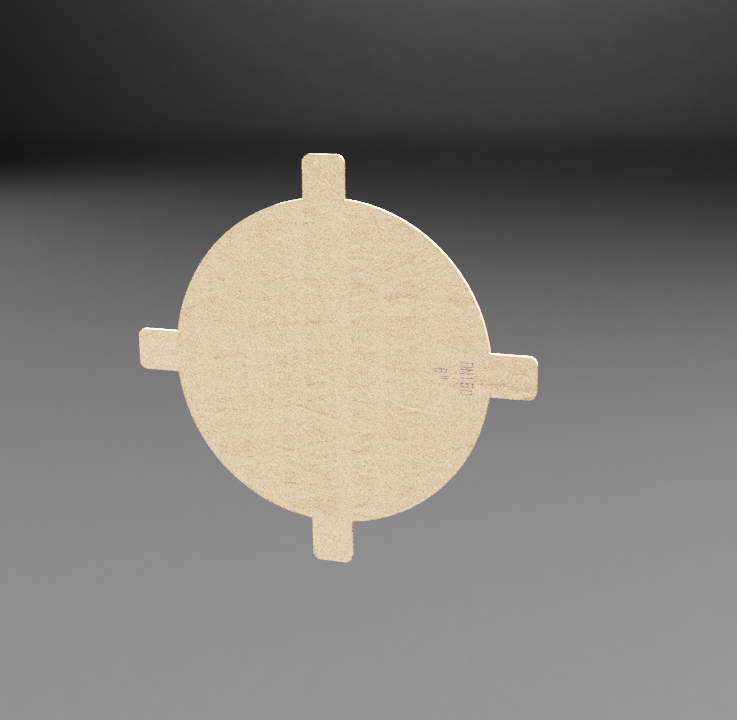

3.Flange discs

These flange discs can be custom-made to fit specific flange dimensions and are designed to cover the entire flange face, including the bolt holes.

They are typically secured to the flange using straps, fasteners, or adhesive.

Flange discs help to protect personnel and equipment from potential leaks or spray-outs of hazardous materials and can also help to maintain the cleanliness of the flange face during storage or transport.

Solid disc covers: These covers are custom-made to fit specific flange dimensions and completely cover the flange face, including the bolt holes. They can be made from various materials such as HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), PTFE (Polytetrafluoroethylene), or metal like stainless steel.

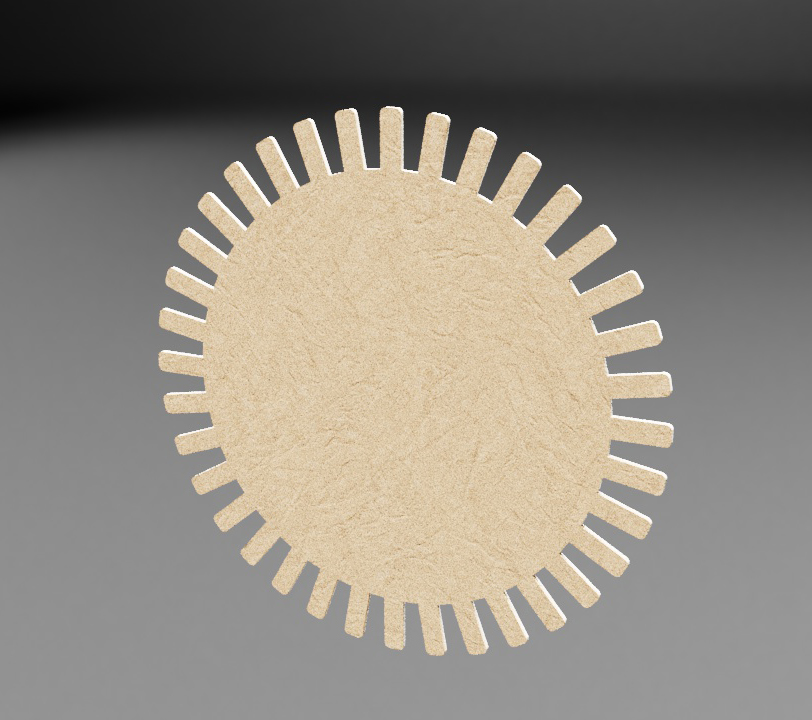

4.Fabric caps

Flange face is the surface where sealing gasket,most designs serrated. During sandblasting and painting,the sand or coating will be damage the face

So we should be protected the flange serrated.face of flange during sandblastiong and painting.

There have 4 type for flange sandblasting and coating protection

1. tape

2.hard plate

3.self adhesive discs

4.Plastic Plugs

How do you protect flange raised surfaces when sandblasting?

Protect the raised-face surface of flanges by self adhesive closed NBR flange discs when sand-blasting to prevent them from being damaged.

What is the material of protecting pipes and tubes

1. Paper

Most usely in masking ,Quick, easy installation and removal,More importmant is cheap and environment

2.Vivly

It is soft type,most used protection thread and polish surface pipe and flange

3.Fabric

Non standward pipe and flange

4.Plastic

for shipping and storage

5.Steel

for thread shipping

What is welding flange raised face protectors

1. Will your company supply samples?

Yes.Free samples and collected freight(or negotiate).Freight charge will refund after confirmation of order.

2. What payment terms do you accept?

T/T,LC, Western Union, Money Gram, Paypal are available for us.We accept 30%T/T in advance and 70% balance against B/L copy.

|

|

|

|

|

|

|

|

© 2022 Wenzhou Leakage Corrosion Hardware Products Co.,Ltd All Rights Reserved. http://www.pipeendcaps.com/ Main products: Self adhesive flange discs | VCI vinyl bolt and nut caps | gap anti-corrosion