Why we need Flange Pressboard Protectors(FPTC) or Pipe Pressboard cover

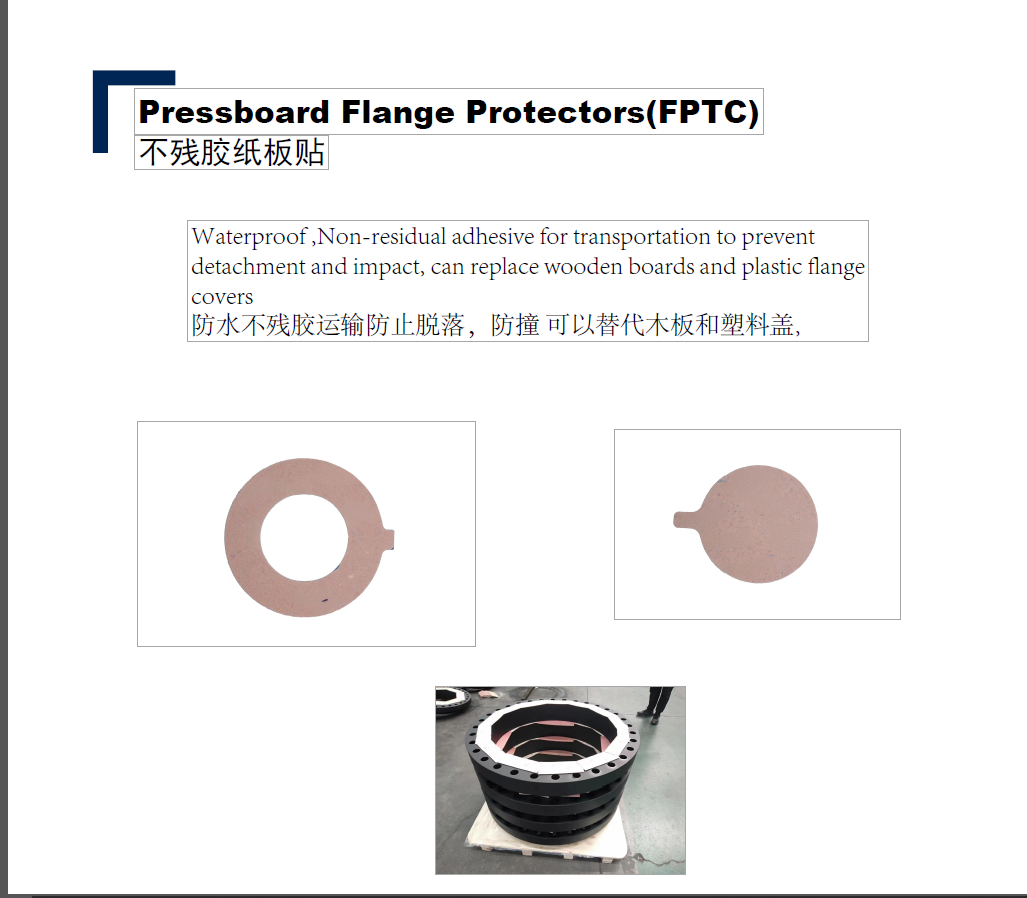

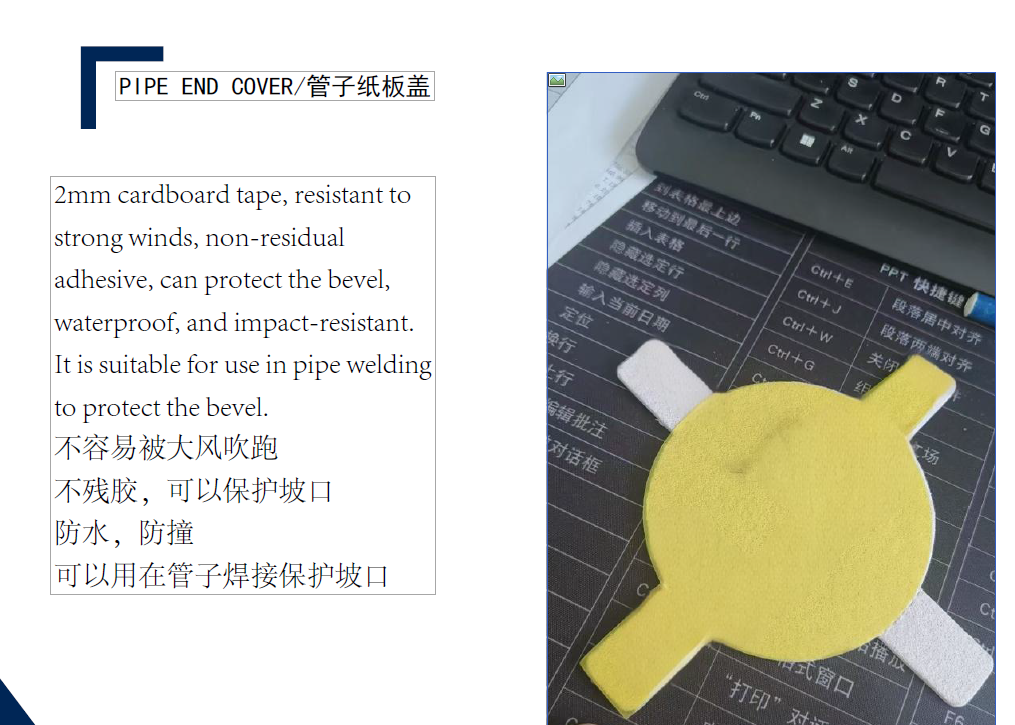

2mm self-adhesive waterproof pressboard flange or pipe end covers arises from several key reasons related to protection, durability, and customization in industrial applications. These covers serve to protect the flange or pipe ends during storage, transport, or periods of inactivity.

1. Protection Against Corrosion and Environmental Damage

- Waterproofing: The 2mm self-adhesive waterproof pressboard cover protects the flange or pipe ends from water, moisture, and other environmental factors that could cause corrosion or damage. It helps to maintain the integrity of the surface, preventing rust or other forms of degradation.

- VCI (Vapor Corrosion Inhibitor): When VCI is added, it helps to prevent rust and corrosion over a longer period, making these covers particularly useful in areas where long-term protection is needed.

2. Welding, Sandblasting, and Coating

- Welding: In some applications, welding might be required to create a more permanent seal or ensure the cover stays securely in place, especially in high-temperature or pressure environments. It ensures that the protective cover is tightly adhered, preventing any exposure to harmful elements.

- Sandblasting: Sandblasting can be used to clean or prepare the surface of flanges or pipes before applying the cover. It ensures a clean surface, improving adhesion between the cover and the pipe/flange surface.

- Coating: Coating can be done to improve corrosion resistance or to create a more robust surface layer. The cover can be coated with protective coatings to withstand harsh environments like chemicals, high temperatures, or saltwater exposure.

3. Self-Adhesive Design

- The self-adhesive feature allows easy application without the need for additional adhesives, tools, or fixtures. This is particularly valuable in environments where quick application is essential.

- The adhesive ensures the cover stays in place securely, providing a tight seal to prevent contaminants from getting inside the pipe or flange.

4. Customization for Exact Specifications

- Special Sizes: Some projects require customized sizes to match specific flange or pipe dimensions. Fabricating covers to exact specifications ensures that the protective covers fit perfectly, reducing the chance of any environmental exposure.

- Custom Materials: The covers can be fabricated from different materials (e.g., pressboard, plastic, rubber) depending on the protection required for the specific environment (e.g., moisture resistance, heat resistance, or UV protection).

5. Cost-Effectiveness and Convenience

- These covers are cost-effective as they provide protection without the need for expensive storage or complex sealing solutions.

- They are lightweight, easy to apply, and remove, making them convenient for temporary or long-term protection during transportation or storage.

Key Benefits of 2mm Self-Adhesive Waterproof Pressboard Covers:

- Moisture and corrosion resistance with the ability to withstand environmental factors.

- VCI protection for rust prevention.

- Customization in terms of size and material to meet specific needs.

- Ease of use with the self-adhesive design, ensuring a secure and tight fit.

-

Versatility for use in welding, sandblasting, coating, and other industrial processes

-