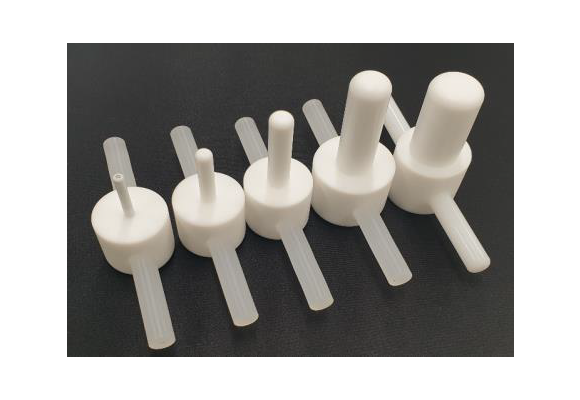

Product Description:

Custom machined plastic parts made of engineering plastics are components manufactured from high-performance plastic materials using machining processes such as CNC (Computer Numerical Control) machining, injection molding, or other precision machining techniques. Engineering plastics are chosen for their excellent mechanical, thermal, chemical, and electrical properties, making them ideal for various applications across industries such as automotive, aerospace, electronics, medical, and more.

Here are some key aspects to consider when discussing custom machined plastic parts made from engineering plastics:

Material Selection: Engineering plastics include a wide range of thermoplastic and thermosetting materials, such as PEEK (Polyether Ether Ketone), PTFE (Polytetrafluoroethylene), Acetal, Nylon, UHMW (Ultra-High Molecular Weight Polyethylene), and others. The choice of material depends on the specific requirements of the part, including temperature resistance, chemical resistance, mechanical strength, and electrical properties.

Design and Engineering: Custom plastic parts require careful design and engineering to meet the intended function and performance requirements. CAD (Computer-Aided Design) software is often used to create 3D models of the parts.

Machining Processes: Depending on the complexity and precision needed for the part, different machining processes can be employed:

CNC Machining: This is a common method for creating custom plastic parts with high precision. It involves computer-controlled cutting and shaping of the plastic material.

Injection Molding: For mass production of plastic parts, injection molding is often used. It involves melting plastic pellets and injecting the molten material into a mold cavity to produce the desired shape.

Extrusion: In this process, plastic material is forced through a die to create parts with a consistent cross-sectional shape, such as plastic tubes or profiles.

Tolerances and Surface Finish: Precision and tolerances must be carefully controlled during machining to ensure that the parts meet the required specifications. Surface finish is also important and can be adjusted based on the application's needs.

Quality Control: Inspection and quality control measures are essential to ensure that the finished parts meet the desired specifications and standards. This may include dimensional inspections, material testing, and other quality checks.

Applications: Custom machined plastic parts made from engineering plastics can be used in a wide range of applications, including but not limited to:

Seals and gaskets

Bearings and bushings

Insulators

Wear-resistant components

Electrical and electronic components

Medical device components

Cost Considerations: The cost of custom machined plastic parts varies depending on factors such as material choice, complexity of the design, batch size, and machining processes used. It's essential to balance performance requirements with cost constraints.

Environmental Considerations: When selecting engineering plastics, consider their environmental impact and recyclability, as sustainability is a growing concern in many industries.

Custom machined plastic parts made of engineering plastics play a crucial role in modern manufacturing, offering a versatile and durable solution for a wide range of applications. The choice of material and manufacturing method should align with the specific needs and performance requirements of the part and its intended application.

You may also like: